Check valve for sewerage - purpose, types and installation

A non-return valve for sewers with a diameter of 110 mm and 50 mm (the most common in apartments and private houses) is able to save the owners of a house or apartment from a lot of trouble associated with blockages and reverse flow of drains. Not expensive and not difficult to install, the device will protect property and prevent unnecessary waste of funds.

The occurrence of sewer backflow can be caused by various reasons, including:

- Misuse sewer system, as a result of which rags, plastic bags and other things block the pipe clearance.

- Appearance during long-term operation sediment on the inner walls of pipes. In this case, not only the clearance decreases, but also a roughness appears on the walls, which contributes to the settling of solid particles and even faster plug formation.

- Incorrect slope of the sewer pipeline. Moreover, both too large and too small a slope contributes to blockages. In order for solid particles not to settle on the inner walls, the water flow that moves them must move at a certain speed. You can change the slope only by completely redoing the system.

- The presence of bends located at right angles, causes the flow of water to change its speed dramatically, while large inclusions can be delayed, forming a plug over time.

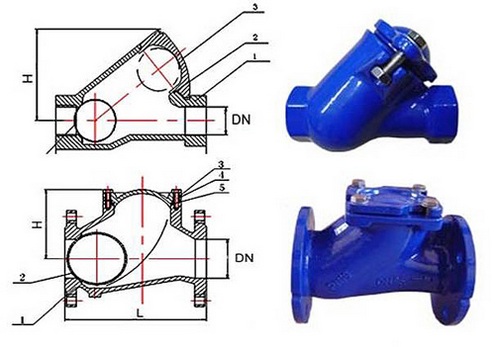

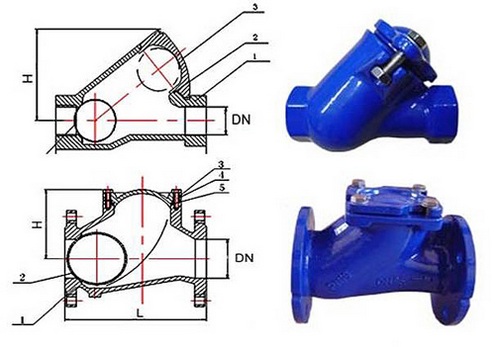

Types of check valves

A non-return valve for sewers is a device that allows water to flow in only one direction and prevents reverse flow. Such devices can be installed at pipe joints, in flanges, or cut into the pipeline using threaded connections.

An element blocking the flow of water can be, for example, "plate", fixed inside the housing in such a way that under the pressure of the flow in the right direction it opens easily, and with reverse current it only presses more tightly against the support ring.

Check valve for sewerage - photo of a plastic model

Check valve for sewerage - photo of a plastic model Also common are ball models, operating on a similar principle, but having a ball inside instead of a plate and characterized by greater reliability, ease of maintenance (to maintain efficiency, the device must be periodically cleaned) and maintainability.

The choice between coupling and flange models is made subject to certain rules:

- Flanged Models are suitable for both vertical and horizontal sections of the sewer pipeline, and coupling - only for vertical ones.

- Union valves are optimal for pipes 2.5 inches or less, and flanged ones are suitable for communications with a diameter of 40 to 600 mm. Thus, the most common sizes - a check valve for sewage 50 mm and 110 mm can be in different designs.

Principle of operation and device

Any sewer check valve, vertical or horizontal, blocks the flow of water in the opposite direction. The check valve for pressure sewage has inlet and outlet pipes of different diameters with a chamber between them. Due to the difference in cross-sectional area, different pressures are created in the nozzles, and the ball in the chamber freely passes water. During the reverse stroke, the pressure in the nozzles changes, and the ball presses the membrane blocking the lumen, completely eliminating the ingress of water from the outlet to the inlet.

In other models, the shut-off "plate" in the presence of pressure rises and passes wastewater, and then immediately assumes a vertical position, thereby preventing the possible passage of wastewater in the opposite direction.

Such devices have a cover fixed with bolts and supplemented with a seal. It is quite easy to open it if necessary to clean the device. Often the check valve in the sewer system is equipped with a shut-off valve.

A plate instead of a ball as a blocking device can be used in large diameter models, such as, for example, a 110 mm sewer check valve, although this condition is not mandatory.

Materials and dimensions of products

The dimensions (mounting diameter) of the check valve for sewage in an apartment depend on the section of the pipeline for which it is intended:

- for toilets choose check valves DN110 mm,

- for the main pipelines of internal systems DN50 mm,

- for external sewage systems - Du150-Du200 mm and more if necessary.

32 mm and 40 mm products are also used.

For the manufacture of non-return sewer valves, the same materials are used as for the production of pipes:

- plastic,

- steel,

- cast iron.

Plastic models are often installed in internal systems from appropriate pipes with a small diameter.

Cast iron pipes and, accordingly, cast iron check valves are recommended for powerful (mainly external) pipelines with a large cross-sectional area, experiencing heavy loads.

Installation of sewer check valves

Do-it-yourself installation of a check valve on a sewer can be done in various ways.

- Models with high capacity can be used for installation on a common sewer pipe. Such options are suitable for private houses, summer cottages and cottages, but not for an apartment in a high-rise building.

- Installing a valve at each drain point in the apartment will prevent an emergency and is especially recommended for residents of the lower (first and second) floors of multi-storey buildings, which are most at risk of flooding when the sewer system is clogged.

- On sewer lines with a reverse slope - without fail to ensure the normal functioning of the system.

Installation Features

It is best to take care of installing a sewer check valve at the stage. Regardless of the type of device (flanged or coupling), the valve will have to be inserted into the finished system, turning off, draining and disassembling the sewer line. It should also be taken into account that the coupling valve has its own length, therefore, when reassembling the line, it will be necessary to adjust the size of the pipes.

- Optimally, if the diameter of the valve exactly matches the diameter of the pipeline. Otherwise, you will have to use adapters, which unnecessarily complicates the design (the more joining elements, the less reliable the communications section).

- Adapters will also be required if the material of the pipes differs from the material of the check valve, however, it is best to initially select a model that is suitable in all respects without complicating your task.

- A preliminary check of the operability (tightness) of the valve can only be carried out visually. Install the product only if it has no visible defects.

Before you install a check valve on the sewer, you need to know the basic rules that must be observed during installation:

- When choosing a place to install a check valve on an internal or external sewer line, consider the need for easy access to the device for inspection, cleaning and repair.

- The orienting arrow, which is provided with each sewer ball check valve, shows the correct direction of water flow, and therefore should point to the sewer collector. The valve, set the other way around, will not interfere with the drain, but will not perform protective functions.

- All connections must be sealed during installation (for example, with FUM tape).

The appearance of noise and vibration of the check valve indicates a violation of its tightness. To restore the device's performance, there is no need to dismantle the system, it is enough to change the shutter or gasket by opening the valve cover.

If we talk about the cost, then for a 110 mm sewer check valve, the price will be about 2,600 rubles (PVC product), and a 50 mm check valve made of the same material will cost approximately 1,150 rubles. These valves also have the ability to forcibly close the drain and use them outdoors.

Do not confuse the check valve and . These are completely different types of equipment.

There are situations when a sewer pump is needed in the kitchen. More about this we.

Non-return valve for sewage photo

Here you can see some photos related to the topic of our article.

- How to make a drain in the bath with your own hands

- Water ball valves: types, classification, device and principle of operation

- Sewerage in a private two-story house - scheme

- Piping in the bathroom: diagram and installation principle

- How to hide pipes in the bathroom with your own hands

- Repair and replacement of drain fittings of the toilet bowl

- Plastic pipes for sewerage in a private house: reliability and quality

Live Journal

Live Journal Facebook

Facebook Twitter

Twitter