What is a switching power supply and how it differs from a conventional analog one. Switching power supply: special features Dual-transistor switching power supply

The principle of implementing secondary power through the use of additional devices that provide energy to the circuit has been used for a long time in most electrical appliances. These devices are power supplies. They serve to convert the voltage to the required level. Power supply units can be either built-in or separate elements. There are two principles for converting electricity. The first is based on the use of analog transformers, and the second is based on the use of switching power supplies. The difference between these principles is quite large, but, unfortunately, not everyone understands it. In this article, we will figure out how a switching power supply works and how it differs so much from an analog one. Let's get started. Go!

The first to appear were transformer power supplies. Their principle of operation is that they change the voltage structure using a power transformer, which is connected to a 220 V network. There the amplitude of the sinusoidal harmonic decreases, which is directed further to the rectifier device. Then the voltage is smoothed by a parallel connected capacitor, which is selected according to the permissible power. Voltage regulation at the output terminals is provided by changing the position of the trimming resistors.

Now let's move on to impulse power supplies. They appeared a little later, however, they immediately gained considerable popularity due to a number of positive features, namely:

- Availability of picking;

- Reliability;

- Opportunities to extend the operating range for output voltages.

All devices in which the principle of pulse power is incorporated are practically indistinguishable from each other.

The elements of a pulsed power supply unit are:

- Linear power supply;

- Standby power supply;

- Generator (RFI, control);

- Key transistor;

- Optocoupler;

- Control circuits.

To find a power supply with a specific set of parameters, use the ChipHunt website.

Let's finally figure out how a switching power supply works. It uses the principles of interaction between the elements of the inverter circuit and it is thanks to this that a stabilized voltage is achieved.

First, the rectifier receives a normal voltage of 220 V, then the amplitude is smoothed using the capacitors of the capacitive filter. After that, the passing sinusoids are rectified by the output diode bridge. Then the sinusoids are converted into high-frequency pulses. Conversion can be performed either with galvanic separation of the power supply from the output circuits, or without such isolation.

If the power supply unit is galvanically isolated, then high-frequency signals are sent to the transformer, which performs the galvanic isolation. The frequency is increased to increase the efficiency of the transformer.

The operation of a pulsed power supply unit is based on the interaction of three chains:

- PWM controller (controls the conversion of pulse width modulation);

- A cascade of power switches (consists of transistors that are switched on according to one of three schemes: bridge, half-bridge, with a midpoint);

- Pulse transformer (has primary and secondary windings that are mounted around the magnetic circuit).

If the power supply is not isolated, then the HSP isolation transformer is not used, and the signal is fed directly to the low-pass filter.

Comparing switching power supplies with analog, you can see the obvious advantages of the former. UPSs are lighter and more efficient. They have a wider supply voltage range and built-in protection. The cost of such power supplies is usually lower.

The disadvantages include the presence of high-frequency interference and power limitations (both at high and low loads).

You can check the UPS using a conventional incandescent lamp. Please note that you should not connect the lamp to the gap of the remote transistor, since the primary winding is not designed to pass direct current, therefore, in no case should it be allowed to pass.

If the lamp is on, then the power supply unit is working normally, if it is not lit, then the power supply unit is not working. A short flash indicates that the UPS is locked immediately after startup. A very bright glow indicates the lack of stabilization of the output voltage.

Now you will know what the principle of operation of a pulsed and conventional analog power supply is based on. Each of them has its own characteristics of structure and work, which should be understood. You can also check the UPS functionality using a conventional incandescent lamp. Write in the comments this article was useful for you and ask any questions of interest on the topic considered.

THIS MATERIAL CONTAINS A LARGE NUMBER OF ANIMATED APPLICATIONS !!!

For the Microsoft Internet Extlorer browser, it is necessary to temporarily disable some functions, namely:

- turn off integrated bars from Yandex, Google, etc.

- turn off the status bar (uncheck):

Turn off address bar:

Optionally, you can turn off the ORDINARY BUTTONS, but the resulting screen area is already enough

Otherwise, you don't need to make any more adjustments - the material is controlled using buttons built into the material, and you can always return the removed panels to their place.

ELECTRICITY CONVERSION

Before proceeding with the description of the principle of operation of switching power supplies, one should recall some details from the general course of physics, namely, what is electricity, what is a magnetic field and how they depend on each other.

We will not go too deeply and we will also keep silent about the causes of electricity in various objects - for this you just need to stupidly reprint 1/4 of the physics course, so let's hope that the reader knows what electricity is not from the inscriptions on the tables "DO NOT GET IN - KILL ! ". However, to begin with, let's recall what it happens, this is electricity itself, more precisely, voltage.

Well, now, purely theoretically, suppose that we have a conductor as a load, i.e. the most common piece of wire. What happens in it when a current flows through it is clearly shown in the following figure:

If everything is clear with the conductor and the magnetic field around it, then we will fold the conductor not into a ring, but into several rings so that our inductance coil manifests itself more actively and let's see what happens next.

At this very place, it makes sense to drink tea and let the brain assimilate what you just learned. If the brain is not tired, or if this information is already known, then we look further

Bipolar transistors, field effect transistors (MOSFETs) and IGBTs are used as power transistors in the switching power supply. Which power transistor to use is decided only by the device manufacturer, since both those, and others and the third have their own advantages and disadvantages. However, it would not be fair not to notice that bipolar transistors are practically not used in powerful power supplies. It is better to use MOSFET transistors at conversion frequencies from 30 kHz to 100 kHz, but IGBTs "like frequencies lower - it is better not to use more than 30 kHz.

Bipolar transistors are good because they close quite quickly, since the collector current depends on the base current, but in the open state they have a rather large resistance, which means that there will be a rather large voltage drop across them, which definitely leads to unnecessary heating of the transistor itself ...

Field ones have very little active resistance in the open state, which does not cause much heat generation. However, the more powerful the transistor, the larger its gate capacity, and rather high currents are required to charge and discharge it. This dependence of the gate capacitance on the power of the transistor is due to the fact that the field-effect transistors used for power supplies are manufactured using MOSFET technology, the essence of which is the use of parallel connection of several field-effect transistors with an insulated gate and made on one crystal. And the more powerful the transistor, the more parallel transistors are used and the gate capacities are summed up.

An attempt to find a compromise is transistors made using IGBT technology, since they are constituent elements. Rumor has it that they turned out purely by chance, when trying to repeat the MOSFET, but instead of field-effect transistors, they turned out not quite field-effect and not quite bipolar. The gate of a low-power field-effect transistor built into it acts as a control electrode, which, with its source-drain, already controls the current of the bases of powerful bipolar transistors connected in parallel and made on one crystal of this transistor. Thus, a rather small gate capacitance and not very high active resistance in the open state are obtained.

There are not so many basic circuits for switching on the power unit:

AUTOMATIC POWER SUPPLIES... A positive connection is used, usually induction. The simplicity of such power supplies imposes some restrictions on them - such power supplies "like" a constant, unchanging load, since the load affects the parameters feedback... Such sources are both single-stroke and two-stroke.

PULSE POWER SUPPLIES WITH FORCED EXCITATION... These power supplies are also divided into one-stroke and two-stroke. The former, although they are more loyal to the changing load, still not very steadily maintain the required power reserve. And audio equipment has a rather large spread in consumption - in the pause mode, the amplifier consumes several watts (quiescent current of the final stage), and at the peaks of the audio signal, consumption can reach tens or even hundreds of watts.

Thus, the only, most acceptable option for switching power supplies for audio equipment is the use of push-pull circuits with forced excitation. Also, do not forget that during high-frequency conversion it is necessary to pay more careful attention to filtering the secondary voltage, since the appearance of power supply noise in the audio range will nullify all efforts to make a switching power supply for a power amplifier. For the same reason, the conversion frequency is moved further from the audio range. The most popular conversion frequency used to be a frequency around 40 kHz, but the modern element base allows converting at frequencies much higher - up to 100 kHz.

There are two basic types of data from impulse sources - stabilized and not stabilized.

Stabilized power supplies use pulse-width modulation, the essence of which is to form the output voltage by adjusting the duration of the voltage applied to the primary winding, and compensation for the absence of pulses is carried out by LC chains connected at the output of the secondary power supply. A big advantage of stabilized power supplies is the stability of the output voltage, which does not depend either on the input voltage of the 220 V mains or on the power consumption.

Unstabilized ones simply control the power unit with a constant frequency and pulse duration and differ from a conventional transformer only in size and much smaller capacitance of the secondary power supply capacitors. The output voltage directly depends on the 220 V network, and has a slight dependence on the power consumption (at idle, the voltage is slightly higher than the calculated one).

The most popular circuits for the power section of switching power supplies are:

Midpoint (PUSH-PULL). They are usually used in low-voltage power supplies, since it has some peculiarities in the requirements for the element base. The power range is quite large.

Half-bridge. The most popular circuit in mains and switching power supplies. Power range up to 3000 W. A further increase in power is possible, but already at a cost it reaches the level of the bridge version, therefore, it is somewhat not economical.

Bridge. This scheme is not economical at low capacities, since it contains a doubled number of power switches. Therefore, it is most often used at powers of 2000 W. The maximum powers are in the range of 10,000 W. This circuitry is the main one in the manufacture of welding machines.

Let's take a closer look at who is who and how it works.

WITH THE MIDDLE POINT

As it was shown, this circuitry of the power unit is not recommended to be used to create network power supplies, however, it is NOT RECOMMENDED does not mean NOT. You just need to more carefully approach the selection of the element base and manufacture of the power transformer, as well as take into account the rather high voltages when wiring the printed circuit board.

This power cascade has received the maximum popularity in automotive auditoriums, as well as in uninterruptible power supplies. However, in this field, this circuitry suffers some inconveniences, namely, limiting the maximum power. And it's not about the element base - today, MOSFET transistors with instantaneous drain-source currents of 50-100 A are not at all scarce. The point is in the overall power of the transformer itself, or rather in the primary winding.

The problem is ... However, for greater persuasiveness, we will use the program for calculating the winding data of high-frequency transformers.

Let's take 5 rings of standard size K45x28x8 with permeability M2000HM1-A, put a conversion frequency of 54 kHz and a primary winding of 24 V (two half-windings of 12 V each) As a result, we get that the power of this core can develop 658 W, but the primary winding should contain 5 turns , i.e. 2.5 turns per half winding. As it is not naturally not enough ... However, it is worth raising the conversion frequency to 88 kHz and you will get only 2 (!) Turns per half-winding, although the power looks very tempting - 1000 watts.

It seems that you can put up with such results and evenly distribute 2 turns throughout the ring, too, if you try hard, you can, but the quality of the ferrite leaves much to be desired, and the M2000HM1-A at frequencies above 60 kHz already heats up quite strongly by itself, but at 90 kHz it is already necessary to blow it.

So whatever one may say, but it turns out a vicious circle - by increasing the dimensions to obtain more power, we reduce the number of turns of the primary winding too much, by increasing the frequency, we again reduce the number of turns of the primary winding, but we also get extra heat.

It is for this reason that dual converters are used to obtain powers over 600 W - one control module issues control pulses to two identical power modules containing two power transformers. The output voltages of both transformers are summed. It is in this way that the power supply of the heavy-duty automotive amplifiers of factory production is organized and about 500-700 W and no more are removed from one power module. There are several ways to add up:

- summation of alternating voltage. The current in the primary windings of the transformers is supplied synchronously, therefore, the output voltages are synchronous and can be connected in series. It is not recommended to connect the secondary windings in parallel from two transformers - a small difference in the winding or the quality of the ferrite leads to large losses and a decrease in reliability.

- summation after the rectifiers, i.e. constant voltage. The most optimal option - one power module provides a positive voltage for the power amplifier, and the other - negative.

- formation of power supply for amplifiers with two-level power supply by adding two identical bipolar voltages.

SEMI-BRIDGE

The half-bridge circuit has quite a few advantages - it is simple, therefore reliable, easy to repeat, does not contain scarce parts, and can be performed on both bipolar and field-effect transistors. IGBT transistors in it also work perfectly. However, she has a weak point. These are feed-through capacitors. The fact is that at high powers a fairly large current flows through them and the quality of the finished switching power supply directly depends on the quality of this particular component.

And the problem is that the capacitors are constantly recharging, therefore, they must have a minimum OUTPUT-COVER resistance, since with a large resistance in this section, quite a lot of heat will be generated and in the end the output will simply burn out. Therefore, it is necessary to use film capacitors as pass-through capacitors, and the capacity of one capacitor can reach a capacitance of 4.7 μF in extreme cases, if one capacitor is used - a circuit with one condensator is also quite often used, according to the principle of the UMZCH output stage with unipolar power supply. If two capacitors of 4.7 μF are used (the point of their connection is connected to the transformer winding, and the free terminals to the plus and minus power buses), then this configuration is quite suitable for powering power amplifiers - the total capacitance for the alternating voltage conversion adds up and as a result it turns out to be equal to 4.7 μF + 4.7 μF \u003d 9.4 μF. However, this option is not designed for pre-term continuous use with maximum load - it is necessary to divide the total capacity into several capacitors.

If it is necessary to obtain large containers ( low frequency conversion) it is better to use several capacitors of smaller capacity (for example, 5 pieces of 1 μF connected in parallel). However, a large number of capacitors connected in parallel greatly increases the dimensions of the device, and the total cost of all the garlands of capacitors is not small. Therefore, if you need to get more power, it makes sense to use a bridge circuit.

For the half-bridge version, the power above 3000 W is not desirable - the boards with pass-through capacitors will be painfully cumbersome. The use of electrolytic capacitors as pass-through makes sense, but only at powers up to 1000 W, since at high frequencies electrolytes are not effective and I start to warm up. Paper capacitors as bushings have shown themselves very well, but their dimensions ...

For greater clarity, we give a table of the dependence of the reactance of the capacitor on the frequency and capacity (Ohm):

| Capacitor capacity |

Conversion frequency |

|||||||

Just in case, we remind you that when using two capacitors (one for plus, the second for minus), the final capacitance will be equal to the sum of the capacitances of these capacitors. The final resistance does not emit heat, since it is reactive, but it can affect the efficiency of the power supply at maximum loads - the output voltage will begin to decrease, despite the fact that the overall power of the power transformer is quite sufficient.

BRIDGE

The bridge circuit is suitable for any power, but it is most effective at high powers (for mains power supplies, these are powers from 2000 W). The circuit contains two pairs of power transistors controlled synchronously, but the need for galvanic isolation of the emitters of the upper pair introduces some inconvenience. However, this problem is quite solvable when using control transformers or specialized microcircuits, for example, for field-effect transistors, you can use IR2110 - a specialized development of International Rectifier.

However, the power section does not make any sense if it is not controlled by the control module.

There are quite a lot of specialized microcircuits capable of controlling the power section of switching power supplies, however, the most successful development in this area is the TL494, which appeared in the last century, nevertheless, it has not lost its relevance, since it contains ALL the necessary nodes for controlling the power section of switching power supplies ... The popularity of this microcircuit is first of all evidenced by its release by several large manufacturers of electronic components at once.

Consider the principle of operation of this microcircuit, which with full responsibility can be called a controller, since it has ALL the necessary nodes.

PART II

What is the actual PWM method of voltage regulation?

The method is based on the same inertia of the inductance, i.e. its not the ability to instantly pass the current. Therefore, by adjusting the pulse duration, you can change the final constant voltage. Moreover, for switching power supplies, it is better to do this in primary circuits and thus save money on creating a power supply, since this source will play two roles at once:

- voltage conversion;

- stabilization of the output voltage.

Moreover, much less heat will be generated in comparison with a linear stabilizer installed at the output of a non-stabilized switching power supply.

For more clarity, it is worth looking at the figure below:

The figure shows an equivalent circuit of a pulse stabilizer in which a generator of rectangular pulses V1 acts as a power switch, and R1 as a load. As can be seen from the figure, with a fixed amplitude of the output pulses of 50 V, by changing the pulse duration, the voltage supplied to the load can be varied over a wide range, and with very small heat fluxes, depending only on the parameters of the power switch used.

We figured out the principles of operation of the power unit, as well as control. It remains to connect both nodes and get a ready-made switching power supply.

The load capacity of the TL494 controller is not very large, although it is enough to control one pair of power transistors of the IRFZ44 type. However, for more powerful transistors, current amplifiers are already needed, capable of developing the required currents at the control electrodes of the power transistors. Since we are trying to reduce the size of the power supply and go away from the audio range, the best use as power transistors will be field-effect transistors made using MOSFET technology.

Variants of structures in the manufacture of MOSFETs.

On the one hand, large currents are not needed to control a field-effect transistor - they open with voltage. However, in this barrel of honey there is a fly in the ointment, in this case, which lies in the fact that although the gate has a huge active resistance that does not consume current to drive the transistor, the gate has a capacitance. And for its charge and discharge, just large currents are needed, since at high conversion frequencies the reactance already decreases to limits that cannot be ignored. And the more the power of the power MOSFET transistor, the greater the capacity of its gate.

For example, take the IRF740 (400 V, 10A), which has a gate capacitance of 1400 pF and the IRFP460 (500 V, 20 A), which has a gate capacitance of 4200 pF. Since both the first and the second gate voltage should not be more than ± 20 V, then we take a voltage of 15 V as control pulses and see in the simulator what happens at a generator frequency of 100 kHz on resistors R1 and R2, which are connected in series with capacitors at 1400 pF and 4200 pF.

Test stand.

When a current flows through the active load, a voltage drop forms on it, and by this value, one can judge the instantaneous values \u200b\u200bof the flowing current.

Drop across resistor R1.

As can be seen from the figure, immediately when a control pulse appears on the resistor R1, approximately 10.7 V drops. With a resistance of 10 Ohm, this means that the instantaneous current value reaches 1, A (!). As soon as the pulse ends at the resistor R1, it also drops to 10.7 V, therefore, in order to discharge the capacitor C1, a current of about 1 A is required ..

Charging and discharging a 4200 pF capacitance through a 10 Ohm resistor requires 1.3 A, since 13.4 V drops across the 10 Ohm resistor.

The conclusion suggests itself - for charging and discharging the gate capacities, it is necessary that the helmet operating the gates of the power transistors withstand rather high currents, despite the fact that the total consumption is quite small.

To limit the instantaneous current values \u200b\u200bin the gates of field-effect transistors, current-limiting resistors from 33 to 100 Ohm are usually used. An excessive decrease in these resistors increases the instantaneous value of the forward currents, and an increase increases the duration of the power transistor in linear mode, which leads to unreasonable heating of the latter.

Quite often, a chain consisting of a resistor and a diode connected in parallel is used. This trick is used primarily in order to unload the control stage during charging and to speed up the discharge of the gate capacity.

Fragment of a single-cycle converter.

Thus, an instantaneous appearance of current in the winding of the power transformer is not achieved, but somewhat linear. Although this increases the temperature of the power stage, it quite significantly reduces the self-induced overshoot that inevitably appears when a rectangular voltage is applied to the transformer winding.

Self-induction in the operation of a single-cycle converter

(red line - voltage on the transformer winding, blue - supply voltage, green - control pulses).

So we figured out the theoretical part and we can summarize some results:

To create a switching power supply, a transformer is needed, the core of which is made of ferrite;

To stabilize the output voltage of a switching power supply, a PWM method is needed with which the TL494 controller is quite successful;

The midpoint power section is most convenient for low-voltage switching power supplies;

The power part of the half-bridge circuitry is convenient for small and medium powers, and its parameters and reliability largely depend on the quantity and quality of the feed-through capacitors;

The power section of the bridge type is more profitable for high powers;

When using a MOSFET in the power section, do not forget about the gate capacitance and calculate the control elements with power transistors, corrected for this capacity;

Since we have figured out the individual nodes, we proceed to the final version of the switching power supply. Since both the algorithm and circuitry of all half-bridge sources are almost the same, then to clarify which element is needed for what we will take apart the most popular one, with a power of 400 W, with two bipolar output voltages.

It remains to note some news:

Resistors R23, R25, R33, R34 are used to create an RC filter, which is extremely desirable when using electrolytic capacitors at the output of pulse sources. Ideally, of course, it is better to use LC filters, but since the "consumers" are not very powerful, you can completely do without an RC filter. The resistance of these resistors can be used from 15 to 47 ohms. R23 is better at 1 W, the rest by 0.5 W is quite enough.

С25 and R28 - snaber that reduces self-induction emissions in the power transformer winding. They are most effective at capacities above 1000 pF, but in this case too much heat is generated on the resistor. They are necessary in the case when there are no chokes after the rectifier diodes of the secondary power supply (the vast majority of factory equipment). If chokes are used, the effectiveness of the snubers is not as noticeable. Therefore, we put them on very rarely and worse power supplies do not work from this.

If some element ratings differ on the board and the circuit diagram, these ratings are not critical, you can use both.

If there are elements on the board that are not in the circuit diagram (usually these are power capacitors), then you can not install them, although it will be better with them. If you decide to install, then not electrolytic capacitors can be used at 0.1 ... 0.47 μF, but electrolytic capacitors of the same capacity as those obtained with them connected in parallel.

On the board OPTION 2 Near the radiators there is a rectangular part that is drilled around the perimeter and the power supply control buttons (on-off) are installed on it. The need for this hole is due to the fact that the 80 mm fan does not fit in height in order to fix it to the radiator. Therefore, the ventilator is installed below the base of the PCB.

SELF-ASSEMBLY INSTRUCTIONS

STABILIZED PULSE POWER SUPPLY

To begin with, you should carefully read the schematic diagram, however, this should always be done before proceeding with the assembly. This voltage converter works in a half-bridge circuit. What is the difference from the rest is described in detail.

Schematic diagram packed with WinRAR old version and is executed on the WORD-2000 page, so there should be no problems with the printout of this page. Here we will consider it in fragments, since we want to preserve the high readability of the circuit, but it does not fit entirely on the eran monitor correctly. Just in case, you can use this drawing to represent the picture as a whole, but it's better to print ...

Figure 1 - mains voltage filter and rectifier. The filter is designed primarily to exclude the penetration of impulse noise from the converter into the network. Completed on L-C based... As an inductance, a ferrite core of any shape is used (rod is better not needed - there is a large background from them) with a wound single winding. The dimensions of the core depend on the power of the power supply, since the more powerful the source, the more interference it will create and the better the filter is needed.

Picture 1.

The approximate dimensions of the cores, depending on the power of the power source, are summarized in Table 1. The winding is wound until the core is full, the diameter (s) of the wire should be selected at the rate of 4-5 A / mm sq.

| Table 1 | ||||

|

POWER SUPPLY POWER |

RING CORE |

W-SHAPED CORE |

||

|

Diameter from 22 to 30 with a thickness of 6-8 mm |

Width from 24 to 30 with a thickness of 6-8 mm |

|||

|

Diameter from 32 to 40 with a thickness of 8-10 mm |

Width from 30 to 40 with a thickness of 8-10 mm |

|||

|

Diameter from 40 to 45 with a thickness of 8-10 mm |

Width from 40 to 45 with a thickness of 8-10 mm |

|||

|

Diameter from 40 to 45 with a thickness of 10-12 mm |

Width from 40 to 45 with a thickness of 10-12 mm |

|||

|

Diameter from 40 to 45 with a thickness of 12-16 mm |

Width from 40 to 45 with a thickness of 12-16 mm |

|||

|

Diameter from 40 to 45 with a thickness of 16-20 mm |

Width from 40 to 45 with a thickness of 16-20 mm |

|||

Here it is necessary to explain a little why the diameter (s) and what is 4-5 A / mm sq.

This category of power supplies belongs to high-frequency. Now let us recall the course of physics, namely the place in which it is said that at high frequencies the current flows not over the entire cross section of the conductor, but over its surface. And the higher the frequency, the more of the conductor cross-section remains unused. For this reason, in pulsed high-frequency devices, the windings are performed using bundles, i.e. take a few thinner conductors and put them together. Then the resulting bundle is twisted slightly along the axis so that the individual conductors do not stick out in different directions during winding, and the windings are wound with this bundle.

4-5 A / mm sq means that the tension in the conductor can reach from four to five Amperes per quadrant millimeter. This parameter is responsible for heating the conductor due to the voltage panic in it, because the conductor has, although not great, but still resistance. In pulse technology, coiled products (chokes, transformers) have relatively small dimensions, therefore they will cool well, therefore, the tension can be used exactly 4-5 A / mm2. But for traditional transformers made on iron, this parameter should not exceed 2.5-3 A / mm2. How many wires and what cross section the diameter plate will help to calculate. In addition, the plate will tell you what power can be obtained by using a particular number of wires of the available wire, if you use it as the primary winding of a power transformer. Open the plate.

The capacity of the capacitor C4 must be at least 0.1 μF, if used at all. Voltage 400-630 V. Formulation if used at all it is not used in vain - the main filter is the choke L1, and its inductance is quite large and the probability of RF interference penetration is reduced to almost zero values.

The diode bridge VD serves to rectify the alternating mains voltage. An assembly of the RS type (end leads) is used as a diode bridge. For 400 W power, you can use RS607, RS807, RS1007 (at 700 V, 6, 8 and 10 A, respectively), since the installation dimensions of these diode bridges are the same.

Capacitors C7, C8, C11 and C12 are necessary to reduce the impulse noise generated by the diodes when the AC voltage approaches zero. The capacitance of these capacitors is from 10 nF to 47 nF, the voltage is not lower than 630 V. However, after several measurements, it was found that L1 copes well with these noises, and to eliminate the influence on the primary circuits, the capacitor C17 is enough. In addition, the capacitances of the capacitors C26 and C27 also make their contribution - for the primary voltage, they are two capacitors connected in series. Since their ratings are equal, the total capacity is divided by 2 and this capacity not only serves for the operation of the power transformer, but also suppresses impulse noise in the primary power supply. Based on this, we refused to use C7, C8, C11 and C12, but if someone really wants to install them, then there is enough space on the board, from the side of the tracks.

The next fragment of the circuit is the current limiters on R8 and R11 (Figure 2). These resistors are necessary to reduce the charging current of the electrolytic capacitors C15 and C16. This measure is necessary because a very large current is required at the moment of switching on. Neither the fuse nor the diode bridge VD are able, even for a short time, to withstand such a powerful current surge, although the inductance L1 limits the maximum value of the flowing current, in this case it is not enough. Therefore, current limiting resistors are used. The power of the resistors of 2 W was chosen not so much because of the heat generated, but because of a rather wide resistive layer capable of withstanding a current of 5-10 A. For power supplies with a power of up to 600 W, you can use resistors with a power of 1 W, or use one resistor with a power of 2 W, it is only necessary to comply with the condition - the total resistance of this circuit should not be less than 150 Ohms and should not be more than 480 Ohms. If the resistance is too low, the chance of destruction of the resistive layer increases, if it is too high, the charging time of C15, C16 increases and the voltage on them does not have time to approach the maximum value as relay K1 will work and the contacts of this relay will have to switch too much current. If wire-wound resistors are used instead of MLT resistors, then the total resistance can be reduced to 47 ... 68 Ohm.

The capacity of the capacitors C15 and C16 is also selected depending on the power of the source. You can calculate the required capacity using a simple formula: ONE WATT OF OUTPUT POWER REQUIRES 1 MKF CAPACITY OF PRIMARY FEED FILTER CAPACITORS... If you have doubts about your mathematical abilities, you can use a plate in which you simply put the power of the power source that you are going to make and see how many and what capacitors you need. Please note that the board is designed for the installation of network electrolytic capacitors with a diameter of 30 mm.

Figure 3

Figure 3 shows the damping resistors whose main purpose is to form the starting voltage. Power not lower than 2 W, installed on the board in pairs, one above the other. Resistance from 43 kOhm to 75 kOhm. It is VERY desirable that ALL resistors are of the same nominal - in this case the heat is distributed evenly. For low powers, a small relay with low consumption is used, so 2 or three damping resistors can be dispensed with. They are installed on the board one above the other.

Figure 4

Figure 4 - power regulator of the control module - in any case there is an intergar stabilizer for + 15V. A radiator is required. Size ... Usually a radiator from the penultimate cascade of domestic amplifiers is enough. You can ask for something in TV workshops - usually 2-3 suitable radiators are found on TV boards. The second is just used to cool the transistor VT4, which controls the fan speed (Figures 5 and 6). Capacitors C1 and C3 can be used for 470 μF at 50 V, but this replacement is only suitable for power supplies using a certain type of relay, in which the coil resistance is quite large. On more powerful sources, a more powerful relay is used and a decrease in the capacitance of C1 and C3 is highly undesirable.

Figure 5

Figure 6

Transistor VT4 - IRF640. Can be replaced with IRF510, IRF520, IRF530, IRF610, IRF620, IRF630, IRF720, IRF730, IRF740, etc. The main thing is that it must be to the TO-220 housing, have a maximum voltage of at least 40 V and a maximum current of at least 1 AND.

Transistor VT1 is almost any direct transistor with a maximum current of more than 1 A, preferably with a low saturation voltage. Transistors in TO-126 and TO-220 cases are becoming equally good, so you can pick up a lot of replacements. If you screw on a small radiator, then even KT816 is quite suitable (Figure 7).

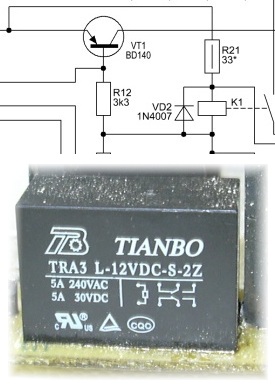

Figure 7

Relay K1 - TRA2 D-12VDC-S-Zor TRA3 L-12VDC-S-2Z... In fact, it is the most ordinary relay with a 12 V winding and a contact group capable of switching 5 A or more. You can use the relays used in some TVs to turn on the demagnetizing loop, just keep in mind that the contact group in such relays has a different pinout and even if it gets onto the board without any problems, you should check which terminals are closed when voltage is applied to the coil. TRA2 differs from TRA3 in that TRA2 have one contact group capable of switching current up to 16 A, and TRA3 has 2 contact groups of 5A each.

By the way - the printed circuit board is offered in two versions, namely with and without relays. In the version without a relay, the system of soft start of the primary voltage is not used, therefore this option is suitable for a power supply with a capacity of no more than 400 W, since it is highly discouraged to include more than 470 μF on the "direct" capacitance without current limitation. In addition, a bridge with a maximum current of 10 A MUST be used as a diode bridge VD, i.e. RS1007. Well, the role of the relay in the version without soft start is performed by the LED. The standby function is saved.

Buttons SA2 and SA3 (it is assumed that SA1 is a power switch) are any type of buttons without latching, for which you can make a separate printed circuit board, or you can screw them in another convenient way. It must be remembered that button contacts are galvanically connected to the 220 V network, therefore, it is necessary to exclude the possibility of their touching during the operation of the power source.

There are quite a few analogs of the TL494 controller, you can use any one, just keep in mind that different manufacturers may have some parameter differences. For example, when replacing one manufacturer with another, the conversion frequency may change, but not much, but the output voltage can change up to 15%.

The IR2110 is, in principle, not a defective driver, and there are not so many analogs for it - IR2113, but IR2113 has a larger number of case options, so be careful - you need a DIP-14 case.

When mounting a board, instead of microcircuits, it is better to use connectors for microcircuits (sockets), ideally collet connectors, but ordinary ones are also possible. This measure will avoid some misunderstandings, since there are quite a few defects among both the TL494 (there are no output pulses, although the clock generator works) and among the IR2110 (there are no control pulses to the upper transistor), so the warranty conditions should be agreed with the seller of microcircuits.

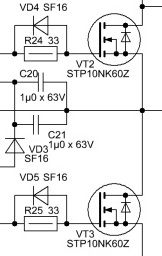

Figure 8

Figure 8 shows the power section. It is better to use fast diodes VD4 ... VD5, for example SF16, but in the absence of such, HER108 is also quite suitable. C20 and C21 - the total capacitance is at least 1 μF, so you can use 2 capacitors of 0.47 μF each. The voltage is at least 50 V, ideally - a film capacitor of 1 μF 63 V (in the event of a breakdown of the power transistors, the film capacitor remains intact, and the multilayer ceramics die). For power supplies with a power of up to 600 W, the resistance of resistors R24 and R25 can be from 22 to 47 Ohms, since the capacitances of the gates of power transistors are not very large.

Power transistors can be any of those listed in Table 2 (TO-220 or TO-220P case).

| table 2 | ||||||

|

Name |

Shutter capacity, |

Max voltage, |

Max current, |

Thermal power, |

Resistance, |

|

|

|

||||||

| If the thermal power does not exceed 40 W, then the transistor case is completely plastic and a larger heat sink is required in order not to bring the crystal temperature to a critical value. Gate voltage for all not more than ± 20 V |

||||||

Thyristors VS1 and VS, in principle, the brand does not matter, the main thing is that the maximum current must be at least 0.5 A and the case must be TO-92. We use either MCR100-8 or MCR22-8.

Diodes for low-current power supply (Figure 9) should preferably be chosen with a short recovery time. HER diodes are quite suitable, for example HER108, but others can be used, for example SF16, MUR120, UF4007. Resistors R33 and R34 for 0.5 W, resistance from 15 to 47 ohms, with R33 \u003d R34. The service winding operating on VD9-VD10 must be rated for 20 V stabilized voltage. It is marked in red in the winding calculation table.

Figure 9

Power rectifier diodes can be used both in TO-220 and TO-247 cases. In both versions of the printed circuit board, it is assumed that the diodes will be installed above each other and connected to the board with conductors (Figure 10). Of course, when installing diodes, you should use thermal grease and insulating gaskets (mica).

Figure 10

It is advisable to use diodes with a short recovery time as rectifier diodes, since the heating of the diodes at idle depends on this (the internal capacitance of the diodes affects and they simply heat up by themselves, even without load). The list of options is summarized in Table 3

| Table 3 | |||

|

Name |

Maximum voltage, |

Maximum current, |

Recovery time, |

The current transformer performs two roles - it is used precisely as a current transformer and as an inductance connected in series with the primary winding of the power transformer, which allows to somewhat reduce the rate of current occurrence in the primary winding, which leads to a decrease in self-induction emissions (Figure 11).

Figure 11

There are no strict formulas for calculating this transformer, but it is strongly recommended to observe some restrictions:

| FOR POWER FROM 200 TO 500 W - RING DIAMETER 12 ... 18 MM FOR OUTPUTS FROM 400 TO 800 W - RING DIAMETER 18 ... 26 MM FOR POWER FROM 800 TO 1800 W - RING DIAMETER 22 ... 32 MM FOR CAPACITIES FROM 1500 TO 3000 W - RING WITH DIAMETER 32 ... 48 MM |

FERRITE RINGS, PERMEABILITY 2000, THICKNESS 6 ... 12 MM |

NUMBER OF FIRST WINDINGS:

3 SCREWS FOR POOR COOLING CONDITIONS AND 5 SCREWS IF THE FAN BLOWS DIRECTLY ON THE BOARD

NUMBER OF SECONDARY WINDINGS:

12 ... 14 FOR THE PRIMARY OF 3 TURNS AND 20 ... 22 FOR THE PRIMARY OF 5 TURNS

MUCH MORE CONVENIENT THE TRANSFORMER TO WIND SECTIONALLY - THE PRIMARY WINDING DOES NOT OVERLAP WITH THE SECONDARY WINDING. IN THIS CASE, UNWINDING-REMOVING THE CIRCUIT TO THE PRIMARY WINDING DOES NOT PRESENT WORK. IN THE FINAL AT A LOAD OF 60% OF THE MAXIMUM AT THE UPPER OUTPUT R27 MUST BE OF THE ORDER 12 ... 15 V

The primary winding of the transformer is wound in the same way as the primary winding of the TV2 power transformer, the secondary with a double wire with a diameter of 0.15 ... 0.3 mm.

To manufacture a power transformer for a pulse power supply unit, use the program for calculating pulse transformers. The core design is of no fundamental importance - it can be toroidal and W-shaped. Printed circuit boards allow you to use both without problems. If the overall capacity of the W-shaped median is not enough, it can be folded into a bag as well as rings (Figure 12).

Figure 12

You can get hold of W-shaped ferrites in TV workshops - not often, but power transformers in TVs fail. The easiest way to find power supplies from domestic TVs 3 ... 5th. Do not forget that if you need a transformer of two or three cores, then ALL cores must be of the same brand, i.e. for disassembly it is necessary to use transformers of the same type.

If the power transformer will be made of 2000 rings, then table 4 can be used.

|

REALIZATION |

REAL |

PARAMETER |

FREQUENCY OF CONVERSION |

||||||

|

MORE POSSIBLE |

OPTIMAL |

STRONG HEAT |

|||||||

|

1 RING |

OVERALL POWER |

||||||||

| VITKOV ON THE FIRST WINDING | |||||||||

|

2 RINGS |

OVERALL POWER |

||||||||

| VITKOV ON THE FIRST WINDING | |||||||||

|

1 RING |

OVERALL POWER |

||||||||

| VITKOV ON THE FIRST WINDING | |||||||||

|

2 RINGS |

OVERALL POWER |

||||||||

| VITKOV ON THE FIRST WINDING | |||||||||

|

3 RINGS |

OVERALL POWER |

|

|

|

|||||

| VITKOV ON THE FIRST WINDING |

|

|

|

||||||

|

4 RING A |

OVERALL POWER |

|

|

|

|

|

|||

| VITKOV ON THE FIRST WINDING |

|

|

|

|

|

||||

| THE NUMBER OF SECONDARY WINDING COURSES IS CALCULATED IN PROPORTION, CONSIDERING THAT THE VOLTAGE ON THE PRIMARY WINDING IS 155 V OR USING THE TABLE ( CHANGE YELLOW CELLS ONLY) | |||||||||

Please note that voltage stabilization is carried out using PWM, therefore, the calculated output voltage of the secondary windings must be at least 30% more than you need. Optimal parameters are obtained when the calculated voltage is 50 ... 60% more than it is necessary to stabilize. For example, you need a source with an output voltage of 50 V, therefore, the secondary winding of the power transformer must be designed for an output voltage of 75 ... 80 V. In the table of calculations of the secondary winding, this factor is taken into account.

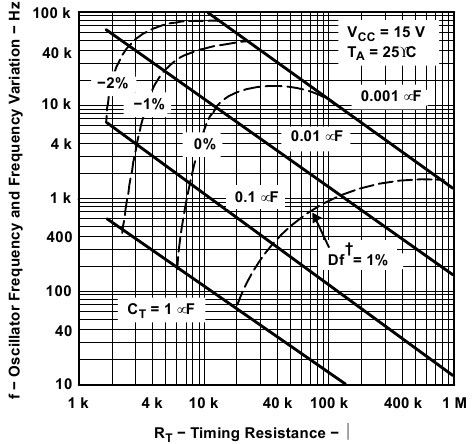

The dependence of the conversion frequency on the ratings C5 and R5 is shown in the graph:

It is not recommended to use a rather large resistance R5 - too large a magnetic field is not far away and pickup is possible. Therefore, we will focus on the "average" R5 rating of 10 kOhm. With this resistance of the frequency setting resistor, the following conversion frequencies are obtained:

|

Parameters obtained from this manufacturer |

Conversion frequency |

||

|

|

|||

(!) Here a few words should be said about the winding of the transformer. Quite often, indignations come, they say, when self-made, the source either does not give the required power, or the power transistors get very hot even without load.

Frankly speaking, we also encountered such a problem using rings 2000, but it was easier for us - the presence of measuring equipment made it possible to find out what was the reason for such incidents, and it turned out to be quite expected - the magnetic permeability of the ferrite does not correspond to the marking. In other words, on "weak" transformers, it was necessary to unwind the primary winding, on the "heating power transistors", on the contrary, to finish it off.

A little later, we refused to use rings, but the ferrite that we use was not makrored at all, so we took drastic measures. A transformer with a calculated number of turns of the primary winding is connected to the assembled and debugged board, and the conversion frequency is changed by a trimmer resistor installed on the board (instead of R5, a trimmer of 22 kOhm is installed). At the moment of switching on, the conversion frequency is set within 110 kHz and begins to decrease by rotating the trimmer slider. Thus, the frequency at which the core begins to enter saturation is found out, i.e. when the power transistors start to warm up without load. If the frequency drops below 60 kHz, then the primary winding is unwound, but if the temperature begins to rise by 80 kHz, then the primary winding is rewound. Thus, the number of turns for this core is found out and only after that the secondary winding is wound using the above plate and the number of turns of the primary for one or another middle is put on the packages.

If the quality of your core is in doubt, then it is better to make a board, test it for operability, and only then make a power transformer using the method described above.

Throttle group stabilization... In some places, the judgment even flashed that he could not work in any way, since a constant voltage flows through him. On the one hand, such judgments are correct - the voltage is really of the same polarity, which means it can be recognized as constant. However, the author of such a judgment did not take into account the fact that, although the voltage is post-constant, it is pulsating and during operation in a given node there is far from one process (current flow), but many, since the choke contains not one winding, but at least two (if the output voltage must be bipolar) or 4 windings, if two bipolar voltages are needed (Figure 13).

The choke can be made both on the ring and on the W-shaped ferrite. Dimensions of course depend on the power. For powers up to 400-500 W, there is enough power supply from the mains filter for TVs with a diagonal of 54 cm and above (Figure 14). The core design is not fundamental

Figure 14

It winds in the same way as a power transformer - from several thin conductors twisted into a bundle or glued into a tape at the rate of 4-5 A / mm2. Theoretically, the more turns the better, so the winding is laid before the window is filled, and immediately in 2 (if a bipolar source is needed) or in 4 wires (if a source with two bipolar voltages is needed.

After the smoothing capacitors, there are output chokes. There are no special requirements for them, dimensions ... The boards are designed for the installation of cores from the mains supply filters for TVs. Wound until the window is filled, section at the rate of 4-5 A / mm sq (Figure 15).

Figure 15

Above was mentioned tape as a winding. Here we should dwell in more detail.

What's better? Bundle or tape? Both methods have their advantages and disadvantages. Making a harness is the simplest way - he stretched the required number of wires, and then twisted them into a bundle with a drill. However, this method increases the total length of the conductors due to internal torsion, and also does not allow achieving the identity of the magnetic field in all conductors of the bundle, and this, albeit not large, but still heat losses.

The production of the tape is more laborious and a little more expensive, since the required number of conductors is stretched and then, with the help of polyurethane glue (TOP-TOP, SPECIALIST, MOMENT-CRYSTAL), is glued into the tape. Glue is applied to the wire in small portions - 15 ... 20 cm in length of the conductor and then holding the bundle between the fingers, as it were, rubbing it, making sure that the wires fit into the tape, like tape bundles used to connect disk media to the motherboard of IBM computers. After the glue has seized, a new portion is applied 15 ... 20 cm of the length of the wires and again smoothed with fingers until a tape is obtained. And so along the entire length of the conductor (Figure 16).

Figure 16

After the glue has completely dried, the tape is wound on the core, and the winding with a large number of turns (usually with a smaller section) is wound first, and higher-current windings are already on top. After winding the first layer, it is necessary to "lay" the tape inside the ring using a cone-shaped peg carved out of wood. The maximum diameter of the peg is equal to the inner diameter of the used ring, and the minimum is 8 ... 10 mm. The length of the cone must be at least 20 cm and the change in diameter must be uniform. After winding the first layer, the ring is simply put on the peg and pressed with force in such a way that the ring is pretty much jammed on the peg. Then the ring is removed, turned over and put back on the peg with the same effort. The peg must be soft enough so as not to damage the insulation of the winding wire, so hard wood will not work for this purpose. Thus, the conductors are laid strictly in the shape of the inner diameter of the core. After winding the next layer, the wire is again "laid" with a peg and this is done after winding each next layer.

After winding all the windings (remembering to use interwinding insulation), it is advisable to warm up the transformer to 80 ... 90 ° C for 30-40 minutes (you can use a gas or electric oven in the kitchen, but you should not overheat). At this temperature, the polyurethane glue becomes elastic and again acquires adhesive properties by gluing together not only the conductors located parallel to the tape itself, but also those located on top, i.e. the layers of the windings are glued together, which adds mechanical rigidity to the windings and eliminates any sound effects, the appearance of which sometimes occurs when the conductors of the power transformer are not properly tightened (Figure 17).

Figure 17

The advantages of such winding are that an identical magnetic field is obtained in all the wires of the ribbon bundle, since they are geometrically located the same in relation to the magnetic field. Such a tape conductor is much easier to evenly distribute around the entire perimeter of the core, which is very important even for standard transformers, and for pulse transformers it is a MANDATORY condition. Using the tape, it is possible to achieve a fairly tight winding, moreover, increasing the access of cooling air to the turns located directly inside the winding. To do this, it is enough to divide the number of necessary wires into two and make two identical tapes that will be wound on top of each other. Thus, the thickness of the winding will increase, but there will be a large distance between the turns of the tape, providing air access to the inside of the transformer.

It is best to use a fluoroplastic film as an interlayer insulation - it is very elastic, which compensates for the tension of one edge that occurs when winding on a ring, has a rather high breakdown voltage, is not sensitive to temperatures up to 200 ° C and is very thin, i.e. will not take up much space in the core window. But it is not always at hand. Vinyl tape can be used, but it is sensitive to temperatures above 80 ° C. Insulating tape based on matter is resistant to temperatures, but has a small breakdown voltage, therefore, when using it, it is necessary to wind at least 2 layers.

Whatever conductor and in whatever sequence you wind the chokes and the power transformer, remember the length of the leads

If the chokes and power transformer are made using ferrite rings, then do not forget that the edges of the ferrite ring should be rounded off before winding, since they are sharp enough, and the ferrite material is quite strong and can damage the insulation on the winding wire. After processing, the ferrite is wrapped with fluoroplastic tape or cloth tape and the first winding is wound.

For complete identity of identical windings, the windings are wound immediately into two wires (it is meant immediately into two bundles) which, after winding, ring out and the beginning of one winding is connected to the end of the other.

After winding the transformer, it is necessary to remove the varnish insulation on the wires. This is the most unpleasant moment, because it is VERY laborious.

First of all, it is necessary to fix the terminals on the transformer itself and to exclude the pulling of individual wires of their bundle under mechanical stress. If the bundle is tape, i.e. glued and warmed up after winding, it is enough to wind several turns on the taps with the same winding wire directly near the transformer body. If a twisted bundle is used, then it must be additionally twisted at the base of the output and also fixed by winding several turns of wire. Further, the outputs are either fired with a gas burner all at once, or they are cleaned one at a time using a clerical cutter. If the varnish is annealed, then after cooling the wires are protected with sandpaper and twisted.

After removing the varnish, stripping and laying the terminal, it is necessary to protect it from oxidation, i.e. cover with rosin gumboil. Then the transformer is installed on the board, all the outputs, except for the output of the primary winding connected to the power transistors, are inserted into the corresponding holes, just in case, the windings should be "ringing". Particular attention should be paid to the phasing of the windings, i.e. for compliance with the beginning of the winding circuit diagram. After the transformer leads are inserted into the holes, they should be shortened so that from the end of the lead to the printed circuit board it is 3 ... 4 mm. Then the twisted lead is "untwisted" and the ACTIVE flux is placed in the soldering place, i.e. it is either quenched hydrochloric acid, a drop is taken on the tip of the match and transferred to the place of soldering. Or, crystalline acetyl-salicylic acid (aspirin) is added to glycerin until a mushy consistency is obtained (both can be purchased at the pharmacy, in the prescription department). After that, the pin is soldered to the printed circuit board, carefully warming up and achieving an even distribution of the solder around ALL tap conductors. Then the output is shortened by the height of the soldering and the board is thoroughly washed with either alcohol (90% minimum), or refined gasoline, or a mixture of gasoline with solvent 647 (1: 1).

FIRST START-UP

Turning on, checking the performance is carried out in several stages to avoid troubles that will definitely arise if there is an error in installation.

1 . To test this design, you will need a separate power supply with a bipolar voltage of ± 15 ... 20 V and a power of 15 ... 20 W. The first switching on is performed by connecting the MINUS OUTPUT of the additional power source to the negative primary power bus of the converter, and the COMMON OUTPUT is connected to the positive terminal of capacitor C1 (Figure 18). Thus, the power supply of the control module is simulated and it is checked for operability without a power unit. Here it is advisable to use an oscilloscope and a frequency counter, but if they are not there, then you can do with a multimeter, preferably arrow (digital do not adequately respond to pulsating voltages).

Figure 18

On pins 9 and 10 of the TL494 controller, the dial gauge switched on to measure the DC voltage should show almost half supply voltage, which indicates that there are rectangular pulses on the microcircuit

Relay K1 should also work

2. If the module is working properly, then the power section should be checked, but again not from high voltage, but using an additional power supply (Figure 19).

Figure 19

With such a sequence of checks, it is very difficult to burn something even with serious installation errors (short circuit between the board tracks, not soldering elements), since the power of the additional unit will not be enough. After switching on, the presence of the output voltage of the converter is checked - of course, it will be much lower than the calculated one (when using an additional source of ± 15V, the output voltages will be underestimated by about 10 times, since the primary power supply is not 310 V but 30 V), nevertheless, the presence of output voltages says that there are no errors in the power section and you can proceed to the third part of the check.

3. The first connection from the mains must be done with current limitation, which can be a conventional 40-60 W incandescent lamp, which is connected instead of a fuse. The radiators should already be installed. Thus, in the event of excessive consumption for any reason, the lamp will light up, and the likelihood of failure will be minimized. If everything is normal, then the output voltage of the resistors R26 is adjusted and the load capacity of the source is checked by connecting the same incandescent lamp to the output. The lamp turned on instead of the fuse should light up (the brightness depends on the output voltage, that is, on what power the source will give. The output voltage is regulated by the resistor R26, however, it may be necessary to select R36.

4 . The functional check is carried out with the fuse in place. As a load, you can use a nichrome spiral for electric ovens with a power of 2-3 kW. Two pieces of wire are soldered to the output of the power source, to begin with, to the shoulder from which the output voltage is monitored. One wire is screwed to the end of the spiral, the second is fitted with a "crocodile". Now, by reinstalling the "crocodile" along the length of the spiral, you can quickly change the load resistance (Figure 20).

Figure 20

It will not be superfluous to make "stretch marks" on the spiral in places with a certain resistance, for example, every 5 ohms. Connecting to the "stretch lines" It will already be known in advance what load and what output power at the moment. Well, the power can be calculated according to Ohm's law (used in the plate).

All this is necessary to adjust the overload protection operation threshold, which should operate stably when the real power is exceeded by 10-15% of the calculated one. It is also checked how steadily the power supply holds the load.

If the power source does not give the calculated power, then some kind of error crept in during the manufacture of the transformer - we look above how to calculate the turns for a real core.

It remains to carefully study how to make a printed circuit board, and this And you can start assembling. The required drawings of the printed circuit board with the original source in LAY format are in

The first

numeral

The second

numeral

Third

numeral

Multi-

body

Tolerance

+/- %

Silver

-

-

-

10^-2

10

Golden

-

-

-

10^-1

5

The black

-

0

-

1

-

Brown

1

1

1

10

1

Red

2

2

2

10^2

2

Orange

3

3

3

10^3

-

Yellow

4

4

4

10^4

-

Green

5

5

5

10^5

0,5

Blue

6

6

6

10^6

0,25

Violet

7

7

7

10^7

0,1

Gray

8

8

8

10^8

Or create a winding, you can assemble a pulse-type power supply with your own hands, which requires a transformer with only a few turns.

At the same time, a small amount of parts is required, and the work can be completed in 1 hour. In this case, the IR2151 microcircuit is used as the basis for the power supply.

For work, you will need the following materials and parts:

- PTC thermistor any type.

- A pair of capacitors, which are selected with the calculation of 1mkf. for 1 W. When creating a design, we select capacitors so that they pull out 220 watts.

- Diode assembly type "vertical".

- Drivers type IR2152, IR2153, IR2153D.

- Field effect transistors type IRF740, IRF840. Others can be selected if they have a good resistance indicator.

- Transformer can be taken from old computer system units.

- Diodesdownstream are recommended to be taken from the HER family.

In addition, you will need the following tools:

- Soldering iron and consumables.

- Screwdriver and pliers.

- Tweezers.

Also, do not forget about the need for good lighting at the workplace.

Step-by-step instruction

circuit diagram

circuit diagram

structural scheme

structural scheme The assembly is carried out according to the drawn circuit diagram. The microcircuit was selected according to the characteristics of the circuit.

The assembly is carried out as follows:

- At the entrance install a PTC thermistor and diode bridges.

- Then, a pair of capacitors is installed.

- Drivers necessary to regulate the operation of the gates of field-effect transistors. If drivers have an index D at the end of the marking, FR107 does not need to be installed.

- Field effect transistors installed without shorting the flanges. When attaching to a radiator, special insulating gaskets and washers are used.

- Transformers installed with shorted leads.

- The output is diodes.

All elements are installed in the designated places on the board and are soldered on the reverse side.

Check

In order to properly assemble the power supply, you need to carefully consider the installation of polar elements, and you should also be careful when working with the mains voltage. After disconnecting the unit from the power supply, no hazardous voltage should remain in the circuit. If assembled correctly, subsequent adjustment is not carried out.

In order to properly assemble the power supply, you need to carefully consider the installation of polar elements, and you should also be careful when working with the mains voltage. After disconnecting the unit from the power supply, no hazardous voltage should remain in the circuit. If assembled correctly, subsequent adjustment is not carried out.

You can check the correct operation of the power supply as follows:

- We include in the chain the output is a light bulb, for example, 12 volts. At the first short start, the light should be on. In addition, you should pay attention to the fact that all elements should not be heated. If something is heating up, then the circuit is assembled incorrectly.

- At the second start we measure the current value with a tester. Let us run the block for a sufficient amount of time to make sure that there are no heating elements.

In addition, it will be superfluous to check all elements with a tester for the presence of a high current after turning off the power.

- As previously noted, the operation of the switching power supply is based on feedback. The considered scheme does not require special feedback organization and various power filters.

- Particular attention should be paid to the choice of field effect transistors. In this case, IR FETs are recommended, which are renowned for their resistance to thermal resolution. According to the manufacturer, they can work stably up to 150 degrees Celsius. However, in this scheme, they do not get very hot, which can be called a very important feature.

- If the transistors are constantly heating, active cooling should be installed. As a rule, it is represented by a fan.

Advantages and disadvantages

The pulse converter has the following advantages:

- High rate Stabilization Factor helps provide power conditions that will not harm sensitive electronics.

- Considered constructions have a high efficiency factor. Modern design options have this figure at the level of 98%. This is due to the fact that the losses are reduced to a minimum, as evidenced by the low heating of the block.

- Large input voltage range - one of the qualities due to which this design has spread. In this case, the efficiency does not depend on the input current indicators. It is the immunity to the voltage indicator that makes it possible to extend the life of the electronics, since jumps in the voltage indicator are a frequent phenomenon in the domestic power supply network.

- Input current frequency affects the operation of only the input structural elements.

- Small size and weightare also popular due to the proliferation of portable and portable equipment. Indeed, when using a linear unit, the weight and dimensions increase several times.

- Organization of remote control.

- Less cost.

There are also disadvantages:

- Availability impulse noise.

- Necessity inclusion of power factor compensators in the circuit.

- Complexity self-regulation.

- Less reliability due to the complication of the chain.

- Severe consequences when one or more circuit elements exit.

When creating such a design on your own, it should be borne in mind that mistakes made can lead to the failure of an electrical consumer. Therefore, it is necessary to provide for the presence of protection in the system.

Device and features of work

When considering the features of the pulse unit, the following can be noted:

- First the input voltage is rectified.

- Rectified voltage depending on the purpose and features of the entire structure, it is redirected in the form of a high-frequency rectangular pulse and fed to an installed transformer or filter operating with low frequencies.

- Transformers are small in size and weight when using a pulse unit due to the fact that increasing the frequency allows you to increase their efficiency, as well as reduce the thickness of the core. In addition, a ferromagnetic material can be used in the manufacture of the core. At low frequency, only electrical steel can be used.

- Voltage stabilization happens through negative feedback. By using this method, the voltage supplied to the consumer remains unchanged despite fluctuations in the input voltage and the load generated.

Feedback can be organized as follows:

- With galvanic isolation, an optocoupler or transformer winding output is used.

- If you don't need to create a junction, a resistor voltage divider is used.

In similar ways, the output voltage is maintained with the required parameters.

Standard switching power supplies, which can be used, for example, to regulate the output voltage when powered , consists of the following elements:

- Input part, high voltage. It is usually represented by a pulse generator. Pulse width is the main indicator that affects the output current: the wider the indicator, the greater the voltage, and vice versa. A pulse transformer stands at the section of the input and output parts, carries out the pulse isolation.

- The output part has a PTC thermistor... It is made of semiconductor and has a positive temperature coefficient. This feature means that when the element temperature rises above a certain value, the resistance indicator rises significantly. Used as a key protection mechanism.

- Low voltage part. An impulse is removed from the low-voltage winding, rectification occurs using a diode, and the capacitor acts as a filter element. The diode assembly can rectify the current up to 10A. It should be borne in mind that capacitors can be designed for different loads. The capacitor carries out the removal of the remaining pulse peaks.

- Drivers extinguish the resulting resistance in the power circuit. During operation, the drivers alternately open the gates of the installed transistors. Work happens at a certain frequency

- Field effect transistors are selected taking into account resistance indicators and maximum voltage when open. At a minimum value, the resistance significantly increases efficiency and decreases heating during operation.

- Typical transformer for lowering.

Taking into account the chosen scheme, you can start creating a power supply of the type in question.

Live Journal

Live Journal Facebook

Facebook Twitter

Twitter